Post by Admin on Jan 2, 2020 7:40:44 GMT

Barrels are normally of precise manufacture and of a heavier cross section than more traditional barrels in order to reduce the change in impact points between a first shot from a cold barrel and a follow-up shot from a warm barrel. Unlike many battle and assault rifles, the bores are usually not chromed to avoid inaccuracy due to an uneven treatment.

When installed, barrels are often free-floated: i.e., installed so that the barrel only contacts the rest of the rifle at the receiver, to minimise the effects on impact point of pressure on the fore-end by slings, bipods, or the sniper's handsSniper-rifle barrels may also utilise a threaded muzzle or combination device (muzzle brake or flash suppressor and attachment mount) to allow the fitting of a sound suppressor. These suppressors often have a means of adjusting the point of impact while fitted.

Military sniper rifles tend to have barrel lengths of 609.6 mm (24 inches) or longer, to allow the cartridge propellant to fully burn, reducing the amount of revealing muzzle flash and increasing bullet velocity.

Since 1985, Schneider Rifle Barrels, Inc. has been manufacturing hand-lapped match-grade stainless steel rifle barrels for a broad spectrum of the shooting industry. We manufacture sporting barrels for the accuracy demanding long range hunter, target barrels for world class competitive shooting disciplines, and specialty barrels for tactical law enforcement and military applications. Champion shooting notable David Tubb (11 time national Champion) has brought our barrels into the competitive field for over 25-years. In the sporting rifle arena, McMillan Rifles, Lazzeroni Arms Company, Red Rock Rifles, Hill Country Rifles and others, utilize Schneider Rifle Barrels on their products.

We are particularly proud that all of the United States Marine Corp M40A-series sniper rifles utilize our barrels exclusively. These are the M40A3, M40A4, M40A5, and now the new M40A6 sniper rifle. This series spans 17-years as the only qualified barrel supplier for this series of rifles. Other federal government entities with similar applications also employ our barrels.

OUR BARREL MAKING PROCESS

We utilize a "pull-button" rifling process to make our barrels. This involves pulling a precision ground hard carbide tool, called a "button," thru a drilled and reamed hole in the barrel blank. This button is larger than the reamed hole and therefore displaces steel to form the groves and lands of the rifling. This process results in a very uniform surface that is hardened as a consequence of the compression of the steel and "work hardening".

The helix for the desired twist-rate is ground into the button to match the desired twist rate of the finished barrel. The button-pulling mechanism is set to match the helix of the button to provide precise twist-rate uniformity. Thereafter, our barrels are stress-relieved according to a specific time and temperature profile, and then contoured to our customer’s desired barrel contour.

Finally, our barrels are individually hand-lapped to provide the desired surface finish and rifled bore uniformity for the full length of the finished barrel.

All of our buttons are precision ground in house. Over the course of our 31-years’ experience this has allowed us to understand the many independent variables associated with rifle button geometry. This led, ultimately, to our innovative P5 polygon rifling geometry. A complete line of calibers and twist rates are available in two distinct rifling geometry configurations. The first rifling form (geometry) is the well recognized 6 land and groove. This form is typical of commercial rifle manufacturers and has existed for a century and a half. Variation in the number of lands is common (6,5,4,3,10 etc.) But geometry is the same, the basic rectangular shape.

P5 RIFLING

The second rifle form available, in addition to the above, is our innovation we refer to as P5 rifling. Some refer to it as "polygon" rifling. Most shooters when referring to polygon have thoughts of the European pistol barrels. Ours however is different but has similarities. Some of our customers call our rifling polygon and that is fine with us, however we call it P5. Have to admit the "P" in P5 does have an association. What is different? Most shooters have looked thru a standard barrel and observed the rectangular shape of the lands and grooves - very well defined by the sharp corners at the transition of land to groove and at the top of the land. The P5 however displays no sharp corners when observed. The sharp corners have been replaced with a radius. The net effect is better seal of bullet to barrel and less damage to the bullet preserving its integrity. The most profound result is an increase in bullet velocity. This is not subjective, a chronograph can measure it. In some instances an excess of 100 fps have been recorded. Another attribute is the barrels foul less. This is subjective; however our customers have been consistently reporting this observation without solicitation. What is telling is the fact that the P5 rifling represents 97% of our sales compared to the conventional rifling and we do not advertise!

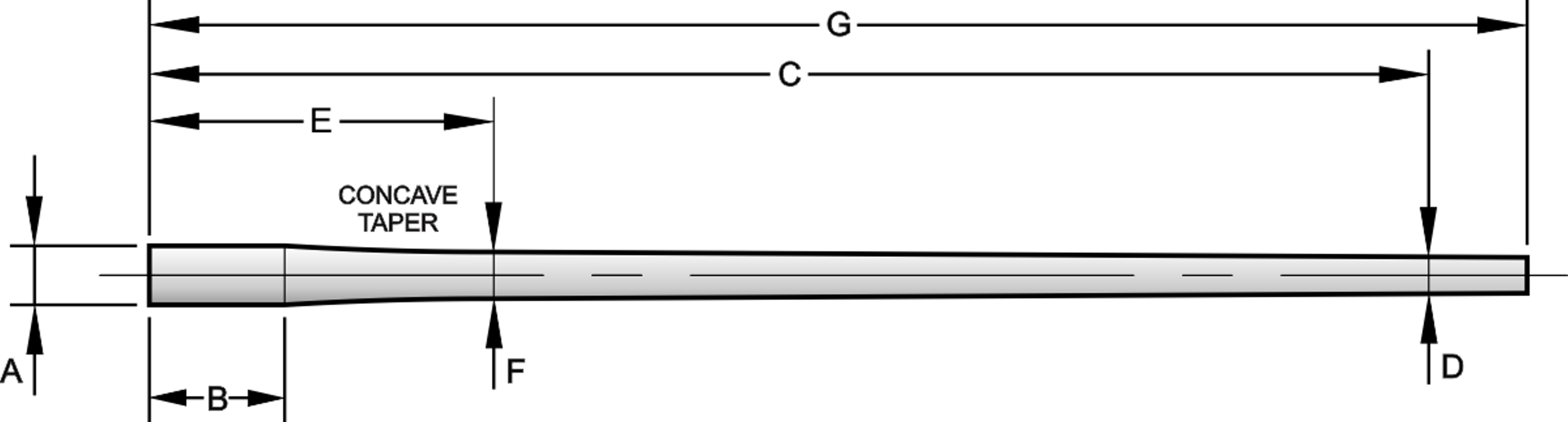

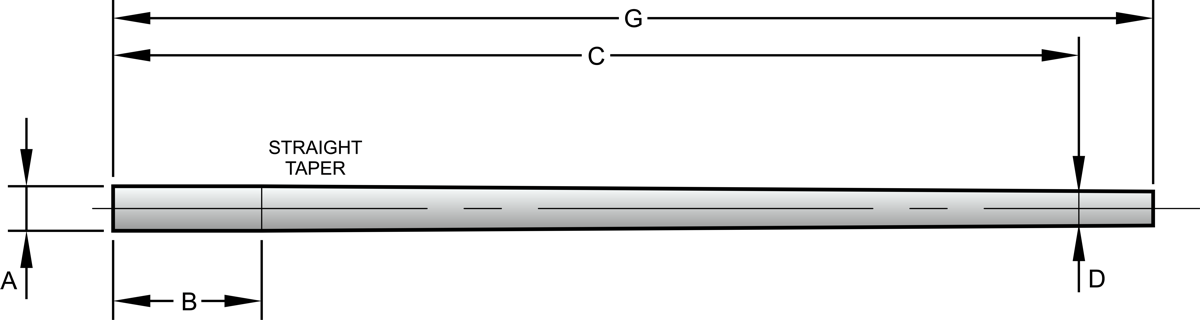

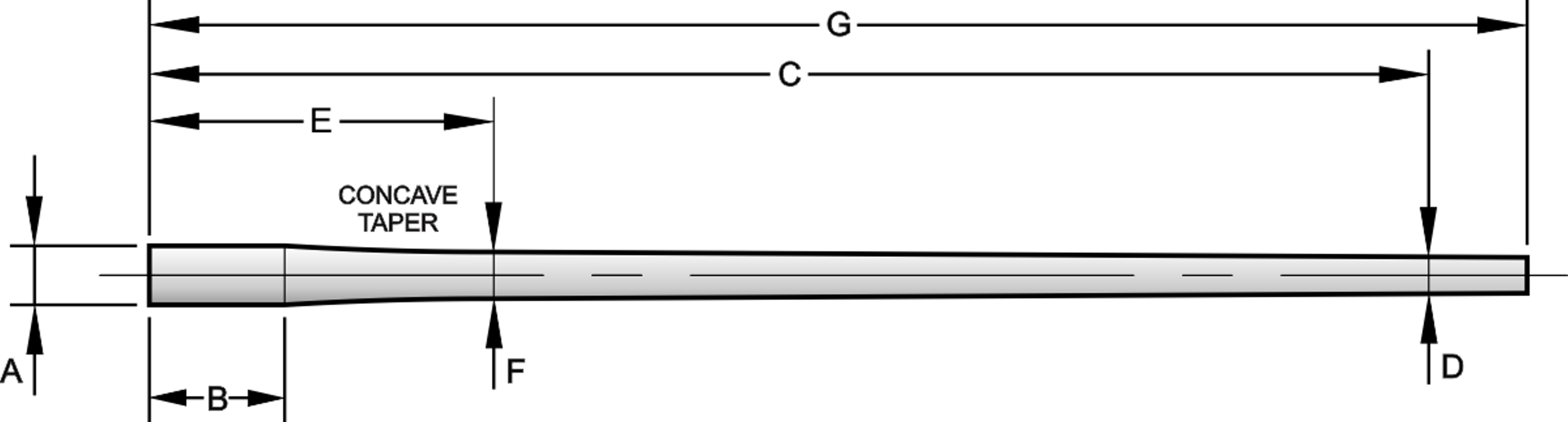

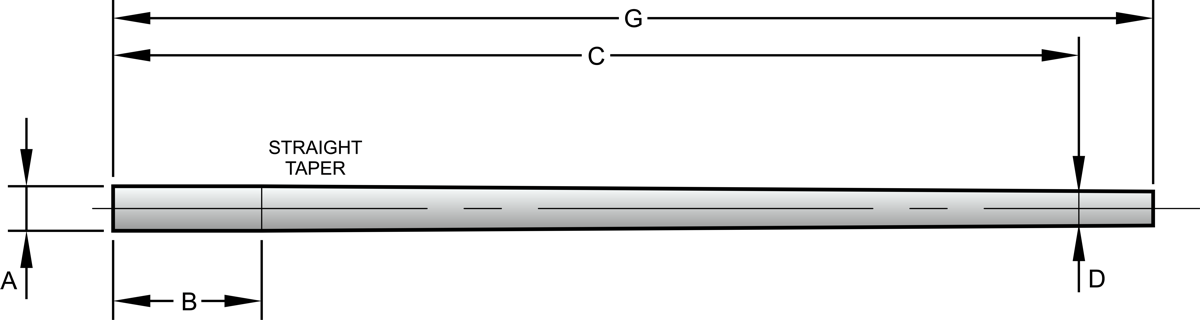

BARREL CONTOURS

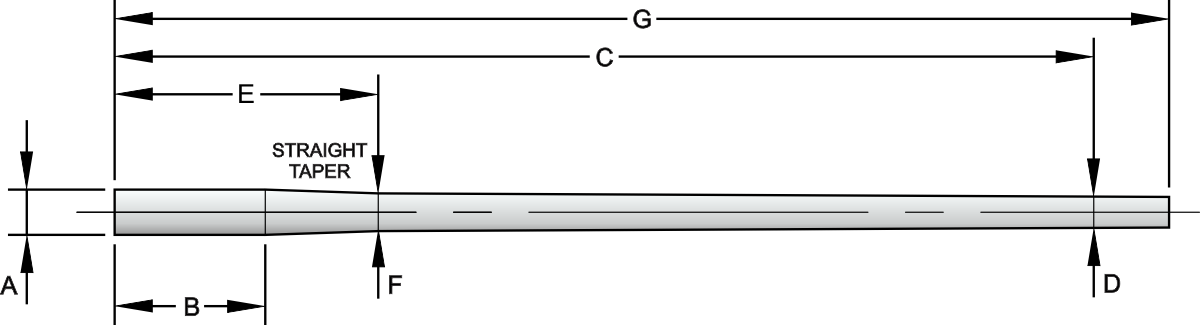

As depicted below we do sporting, target and tactical contours. In addition we will entertain your custom contour. It should be noted that dimension "a" below is typically 1.2 or 1.25 inch for the cylinder diameter where it matches up with the recoil lug or face of the action. This dimension is common with most factory actions. However custom actions sometimes require a larger "a" dimension diameter. Consider this when selecting a contour and we can accommodate accordingly.

We are particularly proud that all of the United States Marine Corp M40A-series sniper rifles utilize our barrels exclusively. These are the M40A3, M40A4, M40A5, and now the new M40A6 sniper rifle. This series spans 17-years as the only qualified barrel supplier for this series of rifles. Other federal government entities with similar applications also employ our barrels.

OUR BARREL MAKING PROCESS

We utilize a "pull-button" rifling process to make our barrels. This involves pulling a precision ground hard carbide tool, called a "button," thru a drilled and reamed hole in the barrel blank. This button is larger than the reamed hole and therefore displaces steel to form the groves and lands of the rifling. This process results in a very uniform surface that is hardened as a consequence of the compression of the steel and "work hardening".

The helix for the desired twist-rate is ground into the button to match the desired twist rate of the finished barrel. The button-pulling mechanism is set to match the helix of the button to provide precise twist-rate uniformity. Thereafter, our barrels are stress-relieved according to a specific time and temperature profile, and then contoured to our customer’s desired barrel contour.

Finally, our barrels are individually hand-lapped to provide the desired surface finish and rifled bore uniformity for the full length of the finished barrel.

All of our buttons are precision ground in house. Over the course of our 31-years’ experience this has allowed us to understand the many independent variables associated with rifle button geometry. This led, ultimately, to our innovative P5 polygon rifling geometry. A complete line of calibers and twist rates are available in two distinct rifling geometry configurations. The first rifling form (geometry) is the well recognized 6 land and groove. This form is typical of commercial rifle manufacturers and has existed for a century and a half. Variation in the number of lands is common (6,5,4,3,10 etc.) But geometry is the same, the basic rectangular shape.

P5 RIFLING

The second rifle form available, in addition to the above, is our innovation we refer to as P5 rifling. Some refer to it as "polygon" rifling. Most shooters when referring to polygon have thoughts of the European pistol barrels. Ours however is different but has similarities. Some of our customers call our rifling polygon and that is fine with us, however we call it P5. Have to admit the "P" in P5 does have an association. What is different? Most shooters have looked thru a standard barrel and observed the rectangular shape of the lands and grooves - very well defined by the sharp corners at the transition of land to groove and at the top of the land. The P5 however displays no sharp corners when observed. The sharp corners have been replaced with a radius. The net effect is better seal of bullet to barrel and less damage to the bullet preserving its integrity. The most profound result is an increase in bullet velocity. This is not subjective, a chronograph can measure it. In some instances an excess of 100 fps have been recorded. Another attribute is the barrels foul less. This is subjective; however our customers have been consistently reporting this observation without solicitation. What is telling is the fact that the P5 rifling represents 97% of our sales compared to the conventional rifling and we do not advertise!

BARREL CONTOURS

As depicted below we do sporting, target and tactical contours. In addition we will entertain your custom contour. It should be noted that dimension "a" below is typically 1.2 or 1.25 inch for the cylinder diameter where it matches up with the recoil lug or face of the action. This dimension is common with most factory actions. However custom actions sometimes require a larger "a" dimension diameter. Consider this when selecting a contour and we can accommodate accordingly.

SPORTING BARREL CONTOURS

Dimensions are in inches

TARGET BARREL CONTOURS

Dimensions are in inches

Dimensions are in inches

TARGET BARREL CONTOURS

Dimensions are in inches

TACTICAL BARREL CONTOURS

Dimensions are in inches

* The M40A3 4, 5 & 6 we supplied to the USMC are identical contours but are finished to different lengths

** The SR60 contour is very popular with law enforcement and often cut to 19-inches on 30-caliber for urban applications.

Note; there are many varieties of tactical barrel contours. Both the straight taper versions and stepped versions as depicted above. Application considerations have been dictating the choice. Example; many of our police depts. Select the SR60 contour since it is lighter than an equivalent straight contour. Also shortening the barrel to 19 inches accommodates ease of handling in and out of a vehicle. The option of adding a suppressor does not make the gun overly long. The straight taper contours have an advantage in high rate of fire applications and also where recoil is perceived to be a factor. Example, we are the supplier of all the USMC M40A3, 4, 5 and now the A6 sniper rifle barrels. The straight taper is a natural fit. Where heavy magnum calibers are used the straight taper is invariably the choice (but not always). Bottomline you have choices and options such as fluting.

Dimensions are in inches

* The M40A3 4, 5 & 6 we supplied to the USMC are identical contours but are finished to different lengths

** The SR60 contour is very popular with law enforcement and often cut to 19-inches on 30-caliber for urban applications.

Note; there are many varieties of tactical barrel contours. Both the straight taper versions and stepped versions as depicted above. Application considerations have been dictating the choice. Example; many of our police depts. Select the SR60 contour since it is lighter than an equivalent straight contour. Also shortening the barrel to 19 inches accommodates ease of handling in and out of a vehicle. The option of adding a suppressor does not make the gun overly long. The straight taper contours have an advantage in high rate of fire applications and also where recoil is perceived to be a factor. Example, we are the supplier of all the USMC M40A3, 4, 5 and now the A6 sniper rifle barrels. The straight taper is a natural fit. Where heavy magnum calibers are used the straight taper is invariably the choice (but not always). Bottomline you have choices and options such as fluting.